BLUEOVAL BATTERY PARK MICHIGAN

BlueOval Battery Park Michigan is a $3.5 billion investment by Ford Motor Company which will produce lithium iron phosphate (LFP) batteries that will power a variety of Ford’s next-generation EV passenger vehicles and pickups.

Read the full announcement here:

Careers at BlueOval Battery Park Michigan

Join our talent community to stay informed of future job openings. Click the button below to submit your information and we will send you alerts regarding future opportunities.

BlueOval Battery Park

BlueOval Battery Park Information Session

On May 3rd 2023 we hosted a virtual information session to discuss the details of BlueOval Battery Park Michigan. Watch the recording here.

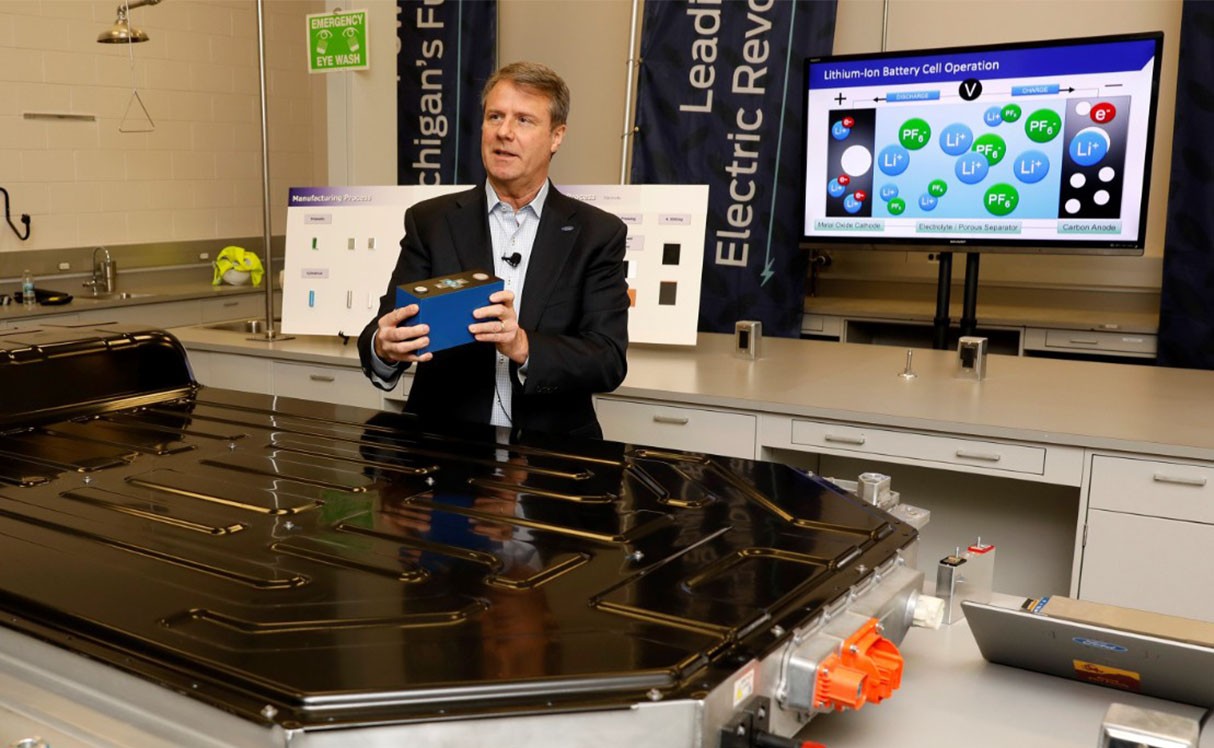

Innovative Battery technology

Ford is the first automaker to commit to build both nickel cobalt manganese (NCM) and lithium iron phosphate (LFP) batteries in the U.S. This helps Ford scale more quickly, making EVs more accessible and affordable for customers.

Even before the new battery plant opens, Ford will introduce LFP batteries on Mustang Mach-E this year and F-150 Lightning in 2024 to increase production capacity, with a goal of reducing wait times for customers.

COMMITMENT TO AMERICAN MANUFACTURING

BlueOval Battery Park Michigan will initially employ 2,500 people when production of LFP batteries begins in 2026.

Ford and its battery tech collaborators have announced $17.6 billion in investment in EV and battery production in the United States since 2019, leading to more than 18,000 direct jobs in the U.S. and more than 100,000 indirect jobs.

BATTERY PRODUCTION BEGINS 2026

Conservation Easement

Ford is ensuring that 245 acres at the southern edge of the site are placed into a conservation easement. This land, along the Kalamazoo River, will be preserved for generations to come and protected against future industrial development. Ford will work with government officials and community leaders to preserve natural resources and recreation near the facility, as part of its commitment to being a good neighbor. The Ford Fund also will contribute resources to help the community explore how to best enjoy this beautiful land.

BlueOval Battery Park Michigan FAQ’s

We receive a lot of questions from our neighbors, stakeholders and partners. We have tried to summarize the most asked questions here. If you don’t find an answer to your question here please email us at blueovalbatteryinfo@ford.com.

Select a Topic

Ford is investing $3.5 billion to build a lithium iron phosphate (LFP) battery plant in Marshall, Mich., called BlueOval Battery Park Michigan. This plant is a wholly owned subsidiary and is part of Ford’s $50 billion+ global push to lead the EV revolution. BlueOval Battery Park Michigan will initially employ 2,500 people when production of LFP batteries begins in 2026.

Production will begin in 2026.

Construction will begin in summer 2023.

Ford conducted a thorough site selection process, considering sites in several states and countries. The analysis included numerous factors including cost, location, and labor availability, among many others. Michigan has been working hard to develop its Marshall Megasite to make it attractive for a manufacturing project like this.

BlueOval Battery Park Michigan will initially employ 2,500 people.

Ford wants local communities around the plant to benefit from the jobs and other opportunities this plant will create. We anticipate that there will be significant new employment opportunities for members of the local community with the right skills and training.

Ford has been planning for this technology for some time – and is the first automaker to commit to build both LFP and NCM batteries in America. Our newest investment in LFP allows us to scale battery production more quickly, create more capacity for high-demand products, meet different customer needs with LFP’s unique benefits – more cost-effectively – and create new American manufacturing jobs. Plus, this reduces the reliance on supply for highly sought-after minerals such as nickel and cobalt, brings new technology to America and strengthens our supply chain.

Both offer advantages. NCM batteries deliver high energy density, so they’re able to handle greater loads in vehicles and can offer longer range. LFP batteries are durable, can be charged to 100 percent repeatedly – making them really good for customers who travel on regular routes instead of long distances – and are less expensive to produce, in part because they do not use nickel and cobalt, which are in high demand.

A new wholly owned Ford subsidiary will manufacture the battery cells as well as own and control the plant. Ford engineers will integrate these LFP battery cells into a variety of our next-generation of electric vehicles. CATL, the world’s largest battery producer, has specific expertise in LFP battery technology. Their only involvement will be as a licensor of battery cell technology to Ford and a contracted service provider.

Our commitment to sustainability includes both what we build and how we build. The design for this facility is still under development, but Ford remains committed to its goal of reducing the effects of our operations and supply chain through world-class facilities like this one and expanding our efforts to: reduce waste; conserve water and energy; and source 100% carbon-free electricity in our manufacturing process.

Ford is ensuring that 245 acres at the southern edge of the site are placed into a conservation easement. This land, along the Kalamazoo River, will be preserved for generations to come and protected against future industrial development. Ford will work with government officials and community leaders to preserve natural resources and recreation near the facility, as part of its commitment to being a good neighbor. The Ford Fund also will contribute resources to help the community explore how to best enjoy this beautiful land.

Contact Us

If you’re interested in pursuing a career with Ford, apply today and become part of our talent community to receive updates on new job openings

For questions about community events or sponsorships, please reach out to

commrels@ford.com